FRP Fuel Storage Tanks

- Home

- FRP Fuel Storage Tanks

Overview

Extraco FRP Fuel Storage tanks are UL approved for both single and double walled Tanks. The inner walls, outer walls and the specifically designed ribs of the double wall FRP tanks act together to form a structural system. They are designed for a life of minimum 30 years. Underground tanks are designed for live loads to take care of the truck load, soil load and vacuum.

Considering all testing conditions as per UL 1316 3rd edition, the tanks are designed for Internal pressure and Hydrostatic pressure. Employs the latest design standard EN 13121-3:2016 for checking all loading conditions, stability of tanks under internal and external pressure.

Specifications

- PESO approved and UL approved for various capacities for fuel storage tanks.

- Uses UL approved resin for fuel storage tanks.

- Equipped with CNC filament winding machine for the manufacturing of tanks up to 4m dia with adequate infrastructure.

- Single wall and double wall tanks.

- Dry Monitoring System and Wet Monitoring System.

- Any customised size and design.

- Single, Double and Triple Compartments can be made upon request.

Product Information

Single wall Fuel Storage Tank

- Single wall tanks fulfill all of the requirements of safe single compartment containment for underground storage or petroleum products.

- Single wall tanks are lightweight, strong and provide a long and trouble free solution.

- Single wall tanks are cheaper in cost.

- Single wall tanks are monitored manually.

Double wall Fuel Storage Tank

- Double wall construction means high strength.

- Secondary containment provides complete long-term protection for petroleum products and for ground against pollution.

- These tanks are available with dry and wet monitoring of the annular space and will detect leaks in inner and outer walls under all conditions.

- Available with exclusive hydrostatic monitoring system.

Applicable Standards

- Design Standard – EN 13121-3:2016, ASME RTP-1, BS 4994

- Testing Standard – UL 1316 3rd Edition

- Specification Standard for Filament Winding Process – ASTM D 3299

- Specification Standard for Contact Moulding Process – ASTM D 4097

Manufacturing process

Extraco tanks are manufactured using CNC filament winding machine by Dual Helical Filament winding process monitored by a fully computerised system. The inner liner thickness of tanks is approximately 2 mm, reinforced with ECR grade glass fiber. The structural wall consists of glass rovings impregnated with resin wound at precisely set helical winding patterns under uniform tension for the various designs. The outer finish consists of resin topcoat.

Resin selection will provide the physical and chemical properties. Terephthalic Resin is usually designed and recommended for underground fuel storage tanks. It is suitable for chemical and fuel storage tanks. Excellent chemical and corrosion resistance to gasoline, fuels, oils, and alcohol blended fuels.

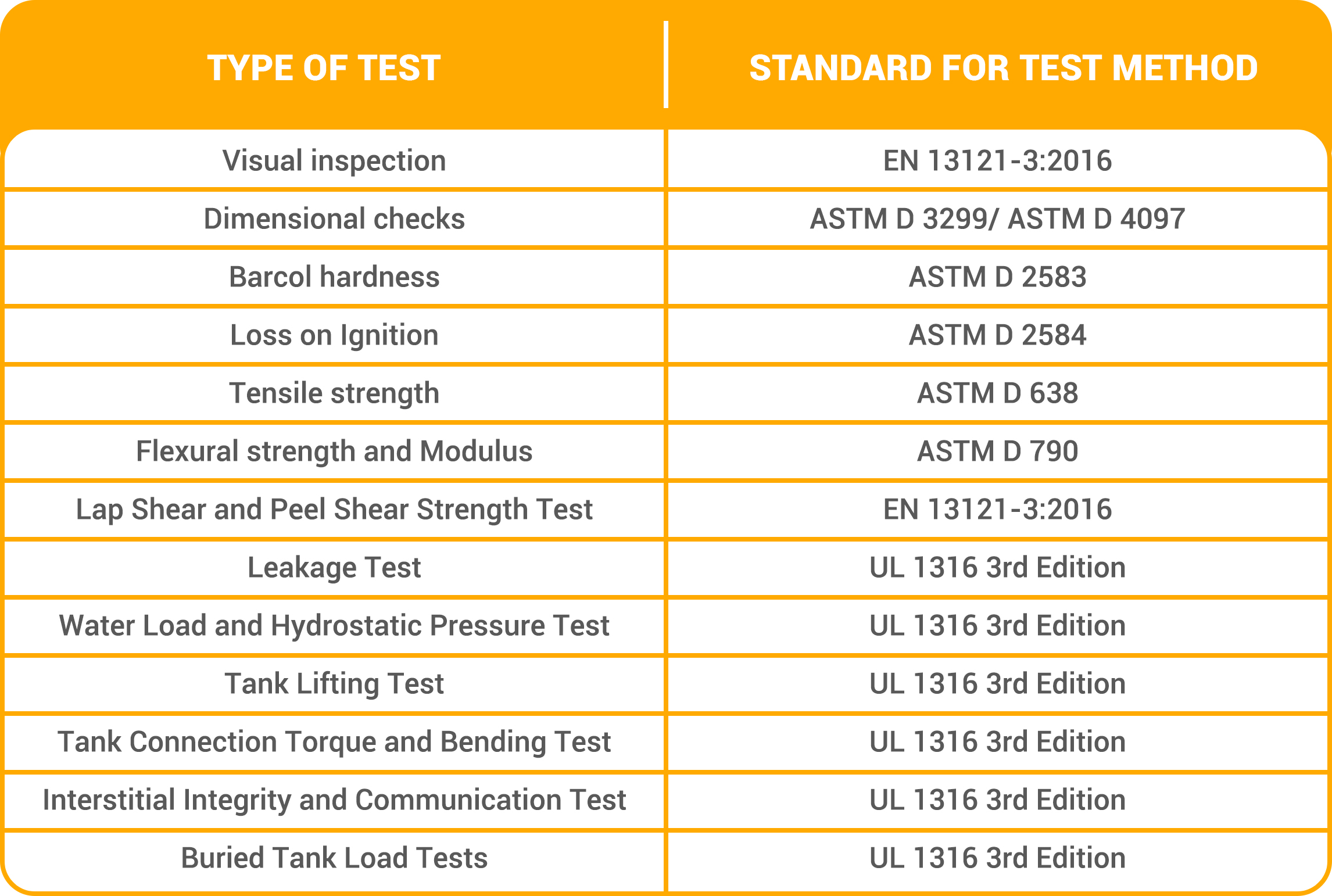

Quality Control & Testing

ExtraCo tanks are subject to quality control testing/inspection and thorough checks as per inspection test plan. All incoming raw materials and finished products are inspected and tested in accordance with international standards in line with the inspection test plan.

Properties

Testing Standards

Application & Usage

Advantages

- Corrosion Resistant.

- Light Weight.

- Easy Installation & Zero Maintenance.

- Compatible to all kinds of fuels and blended fuels.

- Design Life of 30 years.

- Leak Monitoring System.

- High Axial Strength due to its Helical Winding.

- Superior Mechanical Properties due to the Proprietary Raw Material.

- Eco Friendly and doesn’t pollute the Environment.