GRP / GRV / GRE Pipes & Fittings

- Home

- GRP / GRV / GRE Pipes & Fittings

Overview

Glass Fiber Reinforced Plastics “GRP” pipes exhibit excellent adhesion, fatigue-resistance, impact strength, chemical-resistance, and low shrinkage, leading to lesser stresses in the finished pipe, superior mechanical and chemical properties, long-term performance and excellent fatigue-resistance under cyclic loading. Extraco pipes exhibit superior mechanical properties due to its proprietary raw material.

GRP Fittings required for various applications are provided by Extra Co using same material as pipe, formed to suit pipe size and end design, in required elbows, tees, unequal tees, concentric reducers, flanges, blind flanges, puddle flanges, couplings, saddles, wyes, crosses, end caps, etc., Special fittings can be made available upon request.

Specifications

- Diameter Ranges from 25mm to 4000mm.

- Pipes are available in lengths varies from 3 meter to 12 meter.

- Pressure Ranges from 1 bar to 32 bar.

- Stiffness Class Ranges from 2500 N/m2 to 10,000 N/m2 (124 Kpa to 496 Kpa).

Product Information

- GRP pipes use Isophtalic Resin in structural wall and Isophtalic in liner (where applicable) for both underground and aboveground applications, restrained and non-restrained systems, in media temperature up to 60 Deg C.

- GRV pipes use Vinylester Resin throughout for industrial application where specific chemical resistance is required. Used mainly in aboveground applications in media temperature up to 85 Deg C.

- GRE pipes use Epoxy Resin throughout for industrial application in media temperature up to 120 Deg C. Additional external protection can be applied to allow for additional fire-retardance.

Applicable Standards

Specification Standards

- BIS 12709:1994

- BIS 14402:1996

- AWWA C950

- ASTM D2996

- ASTM D5685

Design Standards

- AWWA M45

- ISO 14692-3

Manufacturing process

Extraco GRP/GRV/GRE pipes are manufactured using CNC filament winding machine monitored by a fully computerized system. The inner liner thickness of pipes is minimum 1mm and reinforced with ‘ECR’ glass veil. The structural wall consists of glass rovings impregnated with resin wound at precisely set helical winding patterns under uniform tension for the various designs. The outer finish consists of resin topcoat.

GRP/GRV/GRE fittings required for various applications are provided by Extraco. Using the same material as pipe, formed to suit pipe size and end design, in required elbows, tees, unequal tees, concentric and eccentric reducers, flanges, blanks flanges, puddle flanges, couplings, saddles, wyes, crossed, end caps, etc. Special fittings can be made available upon request.

TYPES OF JOINTS

FLANGED JOINT

To enable connections with steel and to allow for easy assembling and disassembling of process lines, Extra Co pipes and fittings can be supplied with flanges, drilled in accordance with ANSI, BS, DIN or other specifications. Also, special requirements can be met upon request.

RESTRAINED JOINTS

- BUTT & WRAP JOINT

In general these joints will only be used for diameter over 300mm. The preparation of this rigid joint requires good craftsmanship.

NON-RESTRAINED JOINTS

- Bell and Spigot Joint

The socket end of this joint is an integral filament wound part of the pipe with reka ring sitting in a groove built The Spigot end is a machined part on which O-ring seal is positioned. The flexible joint allows for axial movement of the spigot in the socket

- Double Bell Coupling Joint

Short pipes are joined using double bell coupling. The sealing of the joint is achieved by the compression of two electrometric rubber gaskets when the joint is assembled.

Quality Control & Testing

ExtraCo pipes are subject to quality control testing/inspection and thorough checks as per inspection test plan. All incoming raw materials and finished products are inspected and tested in accordance with international standards in line with the inspection test plan.

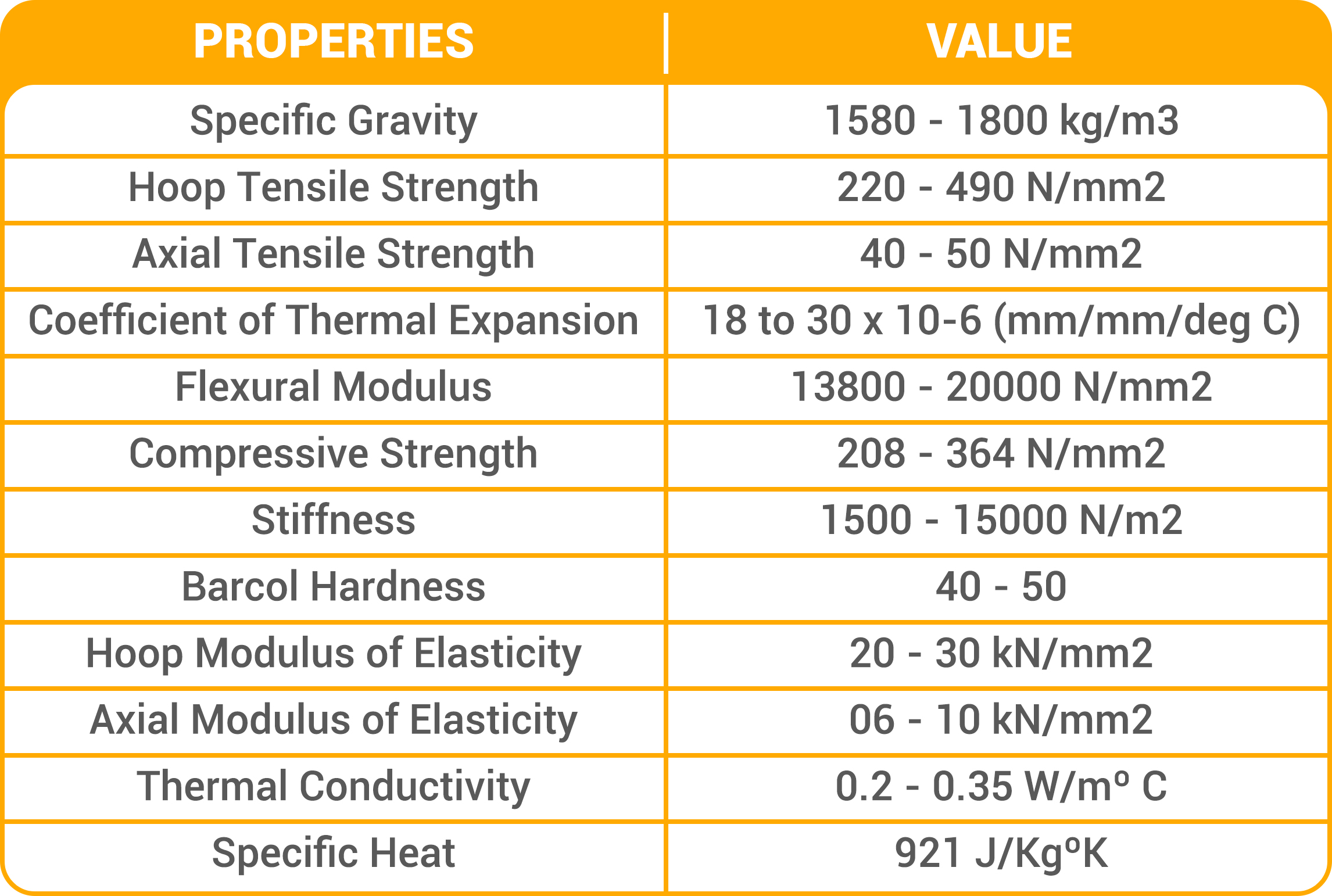

Properties

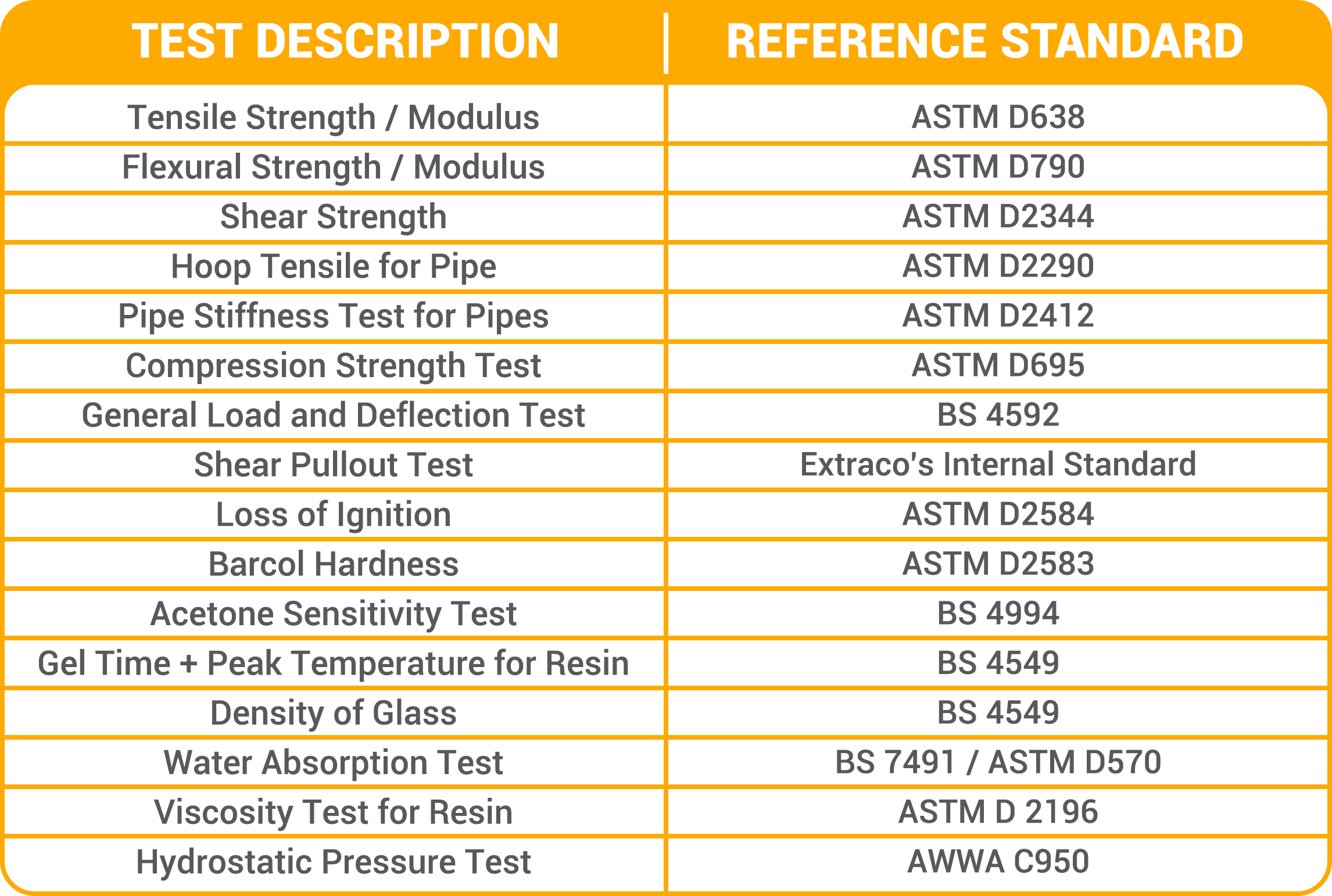

Testing Standards

Application & Usage

INSTALLATION

Underground installation: The customer shall ensure that buried pipes are installed in accordance to Extra Co underground installation instructions.

Aboveground installation: The customer shall ensure that pipes are installed in accordance to Extra Co aboveground installation instructions.